Mixing system

Supervision of an automated system

As part of my semester 4 automation course at ENIB, I had the opportunity to work on the automation of a basic industrial mixing system using a Schneider Electric PLC (Programmable Logic Controller).

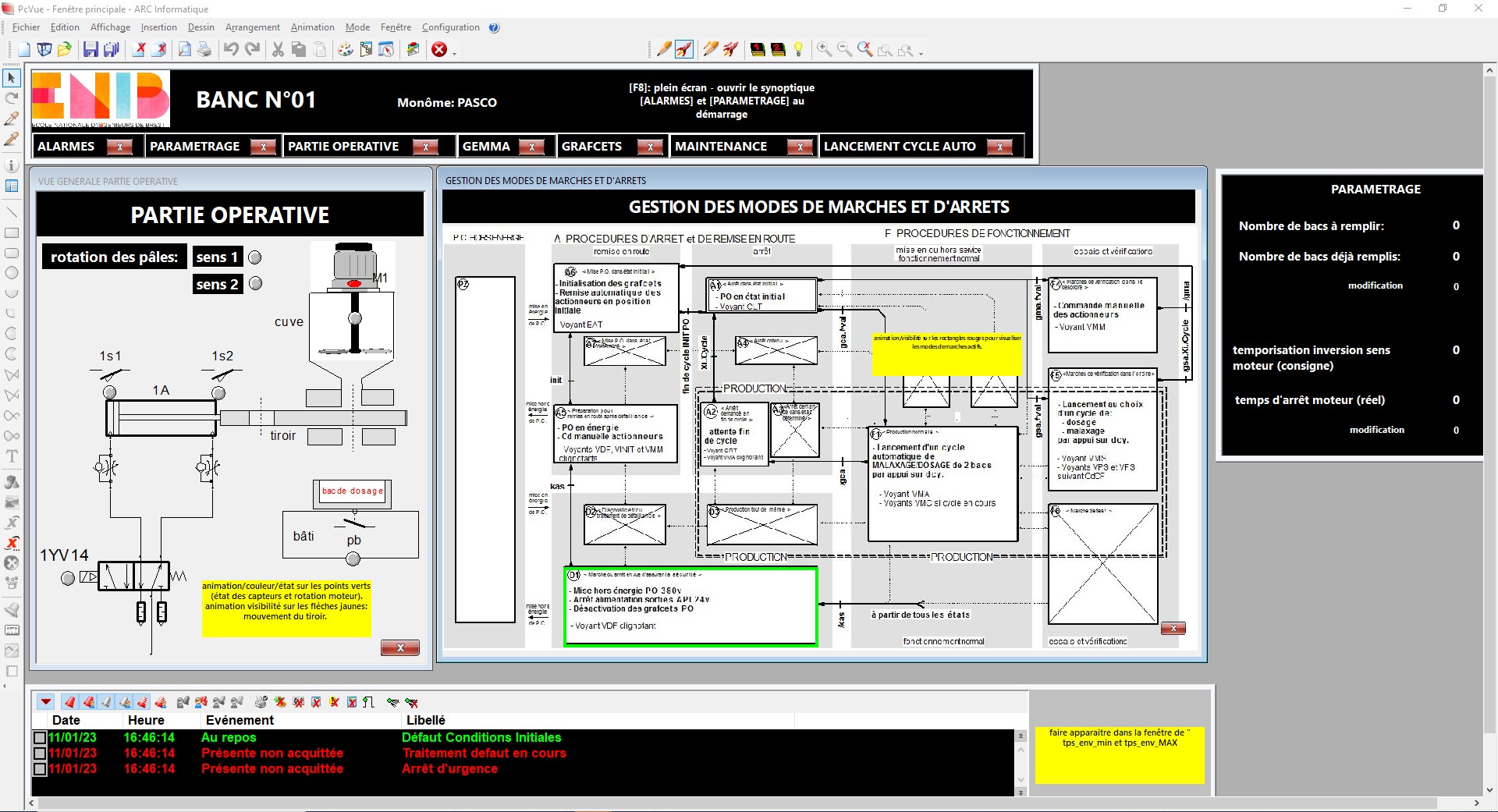

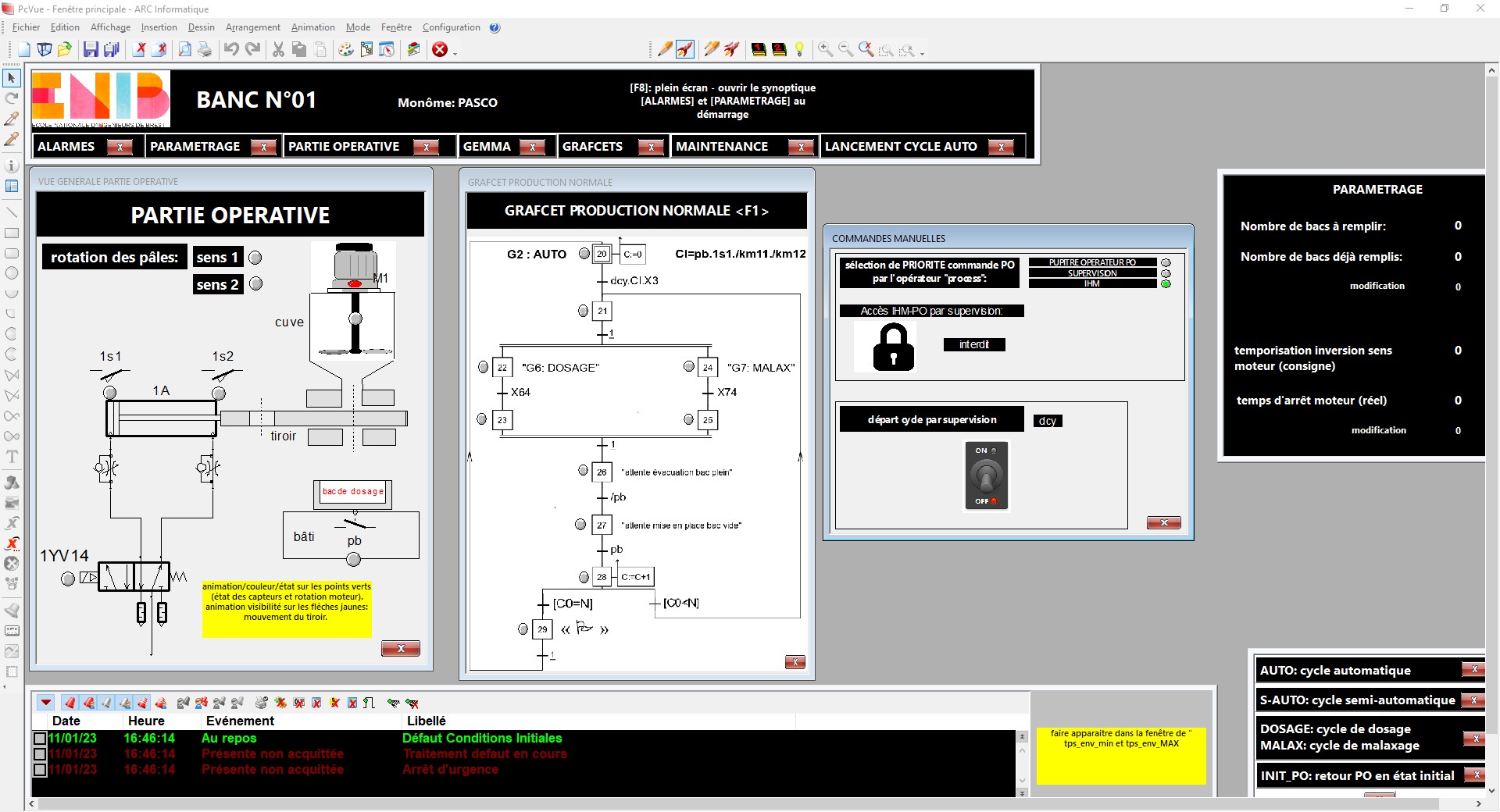

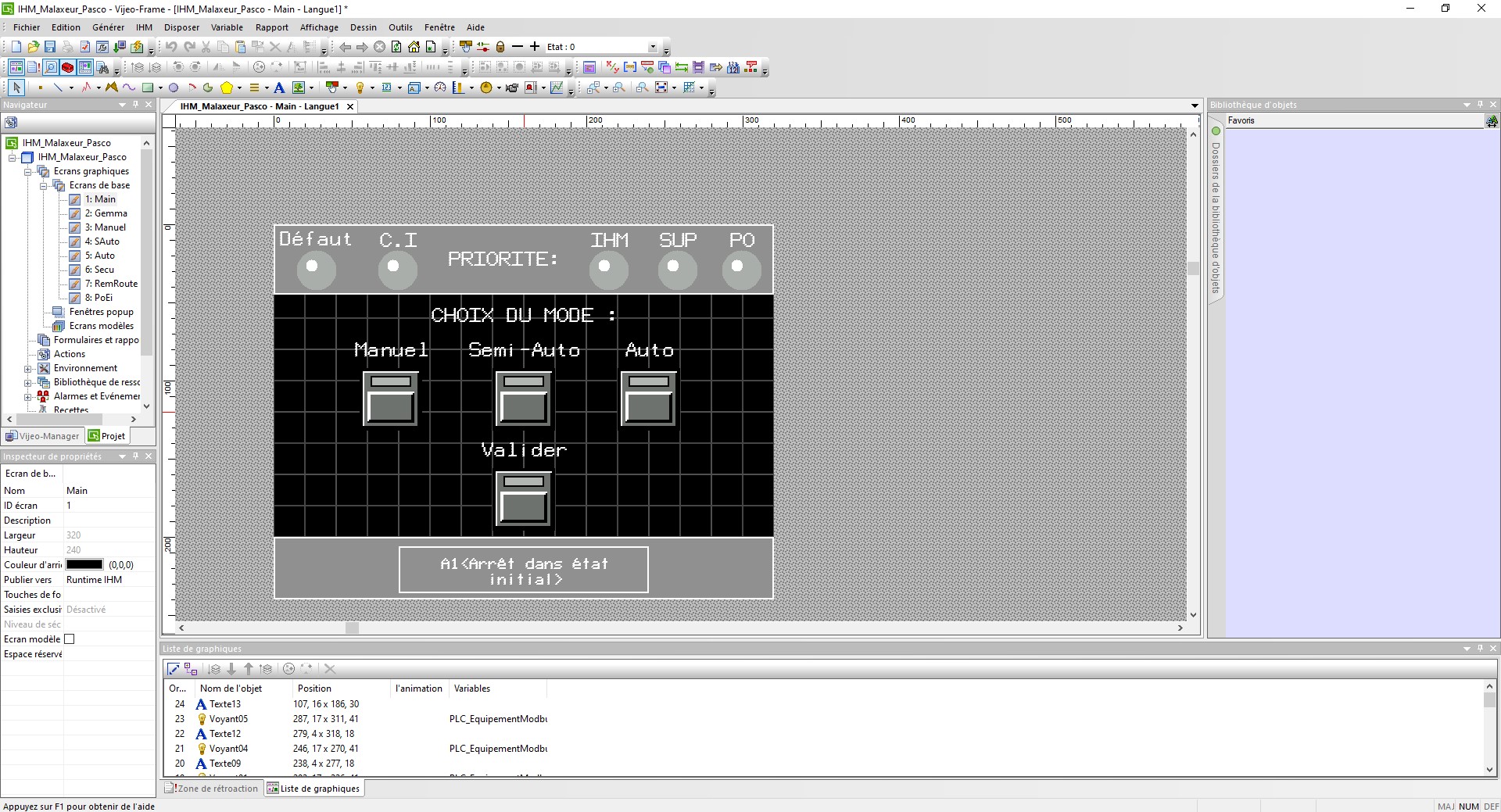

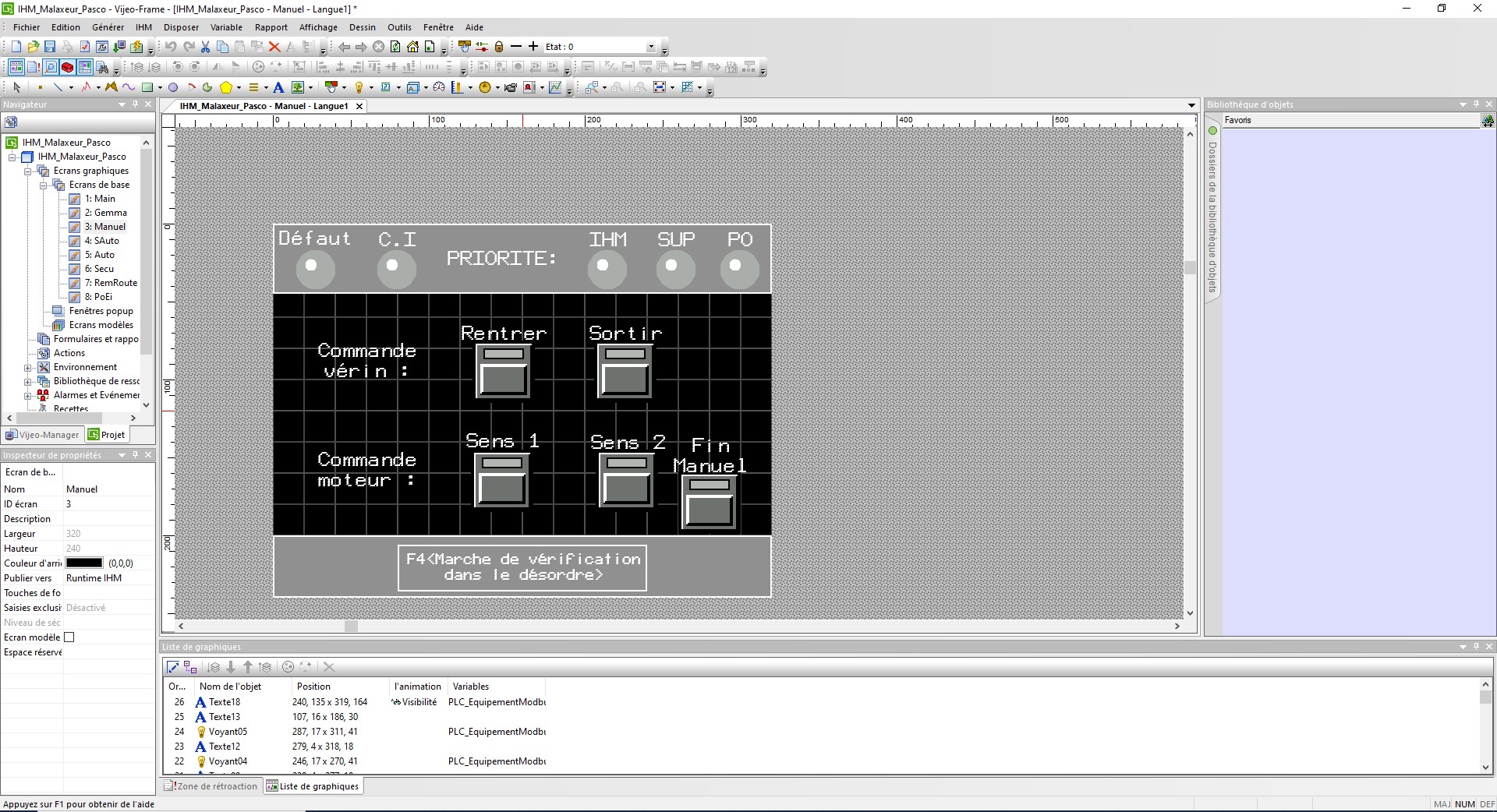

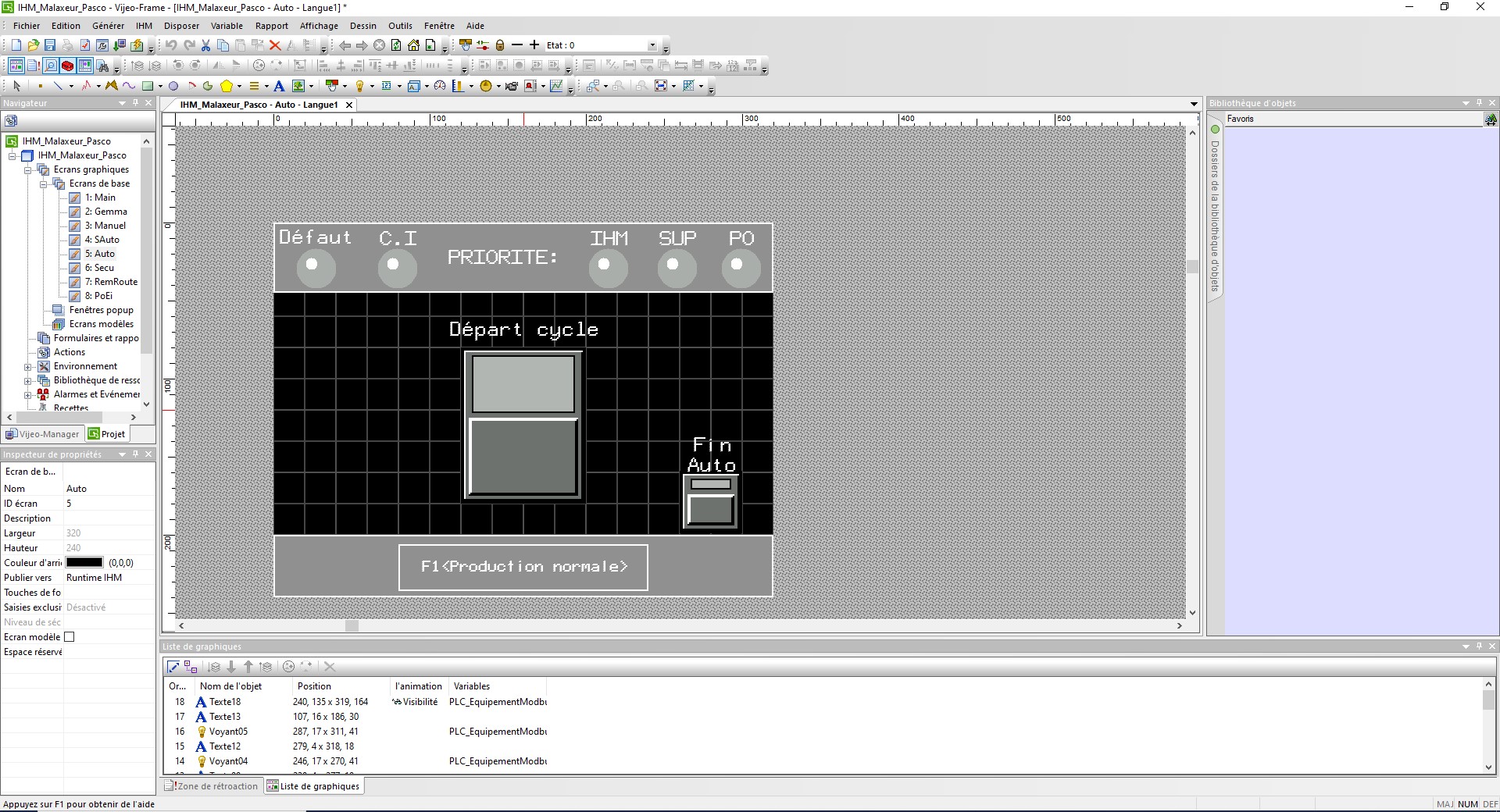

The aim of this project was to introduce the supervision system. The purpose of this is to provide remote access to various machine information, but also to enable cycle start, parameterize certain values and create alarms in the event of a problem, which are kept in a logbook. In addition, the idea was to develop a HMI in parallel with this system, without the use of one disturbing the other (I used an elementary priority system here, for example).

Some images from the HMI development phase:

A few images from the supervisory development phase: